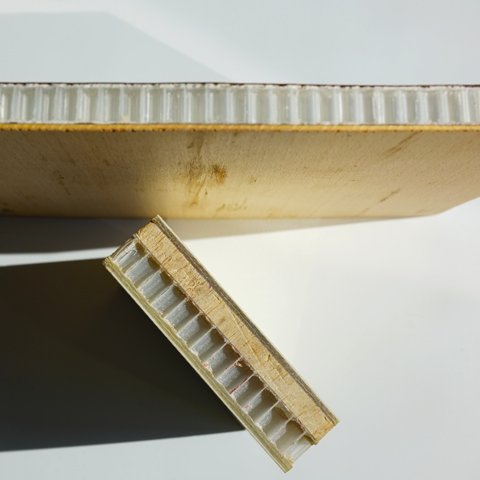

PP honeycomb panel is made of two thin panels firmly bonded to both sides of a thicker honeycomb core material. It is also called a honeycomb sandwich structure. In addition, honeycomb panels also refer to panels that weld a large number of cut-off waveguides together to form a cut-off waveguide array, forming a large opening area and preventing the leakage of electromagnetic waves.

PP honeycomb panels have the advantages of being able to be formed into double-sided fabrics and covered with skin at one time, lightweight and high stiffness, non-toxic and environmentally friendly, shock-absorbing and cold-resistant, sound-proof and heat-insulating, moisture-proof and heat-insulating. It is widely used in interior parts such as trunk lids, trunk partitions, trunk carpet substrates, side decorative panels, ceilings and other interior parts of mid-to-high-end passenger cars. Our PP honeycomb panels have a maximum width of 2.1 meters and a length of 3 meters.

This product has the following advantages:

1. Strong pressure resistance and impact resistance: PP honeycomb panels absorb external forces, thereby greatly reducing the damage caused by impact and collision. It is widely used in many fields such as car bumpers and sports protective gear.

2. Lightweight: PP honeycomb panels are light in weight, which can greatly reduce the load weight of vehicles, thereby increasing the speed of vehicles and reducing transportation costs to a certain extent. It is widely used in interior decoration applications such as shells, ceilings, partitions, decks, and floors of yachts, cars, trains and other vehicles. and the production of luggage.

3. Excellent sound insulation performance: PP honeycomb panels can greatly reduce the spread of sound and can be used as the basic material for sound insulation equipment in a series of noisy vehicles such as cars, yachts, and trains. Construction and decoration materials for places with high requirements.

4. Excellent thermal insulation performance: The PP honeycomb panel has excellent thermal insulation performance and can effectively block the spread of heat. Its internal temperature is relatively stable, and it has been well used in the boxes of refrigerated trucks and vans.

5. Water resistance and strong corrosion resistance: Due to the characteristics of its raw materials, it can be used in environments with high water content and strong corrosion for a long time. It is widely used in the construction of docks and the manufacture of offshore floating rafts. Due to the permeability of the product, it has also been widely used in fountains. It can also be used in air filtration and purification equipment with activated carbon.

Next, we will introduce two of the PP honeycomb panels:

1. FRP honeycomb panel

FRP honeycomb panel FRP is a very perfect panel. Using polyester-reinforced plastic, multi-axial high-strength glass fibre and PP honeycomb panels as the main materials, it is formed in a special mould through constant temperature vacuum pressure, adsorption, glueing and solidification. The product structure is reasonable and the technology is advanced.

FRP honeycomb panels have the following advantages:

a. Light weight b. High strength, c. Waterproof and moisture-resistant, d. Anti-corrosion, e. Anti-ageing, f. Flame retardant, g. No pollution, it is an environmentally friendly product.

2. Plastic honeycomb panel

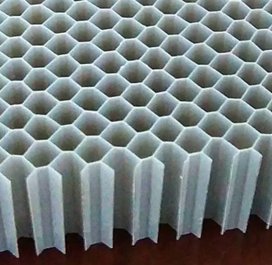

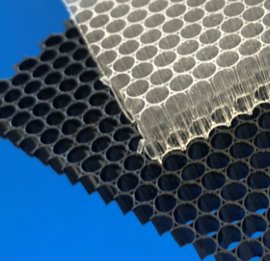

Plastic honeycomb is a honeycomb material made of laminated plastic sheets such as PVC, PET, PP, etc. It has the characteristics of lightweight and high strength. The current honeycomb hole shape: hexagonal, round holes and semi-circular groove honeycomb composite panels.

hexagonal round holes semi-circular

Honeycomb panel is composed of two surface panels and a honeycomb middle layer filled in to ensure that the two surface panels work together. The design idea of the honeycomb panel structure comes from the I-beam structure: the surface plate is equivalent to the wing plate of the I-beam, which mainly bears the normal stress; the middle honeycomb layer is equivalent to the web of the I-beam, which mainly bears the shear stress. The two dashboards have high structural strength and a large cross-sectional moment of inertia, so they have good stiffness and high bending strength.

Qingdao Achieving Honeycomb Panel Co., Ltd. has been committed to producing plastic honeycomb core materials for nearly 20 years. We have supplied many manufacturers with plastic non-woven honeycomb cores (pp honeycomb core with non-woven surface) that match their requirements and assisted in clients' project development: testing and modification. And can be composite with many kinds of surfaces to meet different requirements. The customized options can include the size, shape, aperture, thickness, etc. The most commonly used standard thicknesses are 20mm 25mm and 15mm. Achieving has a complete quality control system to implement customers' weight and tolerance standards strictly and has reached the production capacity of large-scale supply. If you are interested in the pp honeycomb panel, welcome to visit our website: www.chinahoneycomb.com and www.cnhoneycomb.com.